8 rows Just fill out this quick form and well get back to you as soon as possible. Flanged joints with gaskets are very common in pressure vessel and piping systems and are designed mainly considering internal pressure.

What Are M And Y Gasket Design Constants And How Are They Used Pumps Systems

At the inside edge the pressure is the pressure in the pipe.

. The common Grade B steels can be used in service to 50F if the pipe and. The semi-metallic design combines metal and a soft material the metal to withstand the pressure temperature and attack of the confined fluid and the soft material to impart resilience. Their applicable pressure range is from 1000 to 15000 psi.

Ring-joint gaskets are commonly used in grooved flanges for high-pressure-piping systems and vessels. So for example a class 150 gasket is designed to seal under a load of up to 150 lbs of pressure in a class 150 flange. Prevention of fluid leakage is the prime requirement of flanged joints.

HOBT ROTT EN 13555. Those shown in the figure above are the twelve sections of the code. The design values and other details given in this table are suggested only.

Standard Custom Designs including Quick-Open ASME available Engineer Support. The gasket should be attached to the flange surfaces and be compressed to reduce the internal voids and spaces. For example NAF and metallic gasket.

α INTRODUCTION- PRESSURE VESSELS ARE VESSELS WORKING UNDER INTERNAL OR EXTERNAL VACUUM PRESSURE WITH VARIOUS. The ASME rules reduce the width of the gasket. Tanks with storage pressures above a gauge pressure of 15 psi 100 kPa shall be designed and constructed in accordance with recognized engineering standards.

Cleaver-Brooks has taken great care to insure our factory selected and engineered gaskets perform to to our specifications. Fired pressure vessels shall be designed and constructed in accordance with. Various LV modules can be used for the flange gasket bolt calculation varying from a simple rough design to a more complex and precise design.

Gasket Selection Gasket Design Gasket Installation 3 Overcoming Flange Imperfections Distortion trough Surface imperfections Scorings Non-parallel mounted flanges TheGasket A gasket is a compressible material or a combination of materials which when clamped between two stationary members prevents the passage of the media across. Metallic gaskets have good stress capacity property and can seal the pressure. These joints are not generally pressure-actuated.

Per this for 12 bolt the E dimension is 58 gasket width is 1 14 and with a 58 hole the ligament is 516. Pressure Vessel Gaskets must handle the elevated steam and hot water temperatures as well as the maximum design pressure of a boiler to create a positive seal. We design these quite often.

1235 psi 85 Bar Sizing to meet ASME B165 and special flanges Complies with the requirements of FDA21 CFR 1771550. This load is a design rule not a predictor of. I am not a big fan of full face gaskets.

These gaskets are designed to give very high gasket pressure with a moderate bolt load. Presently for high pressure application metallic gasket is the advance solution which is been used for sealing the pressure vessel. Ad Designs Manufactures A Broad Range Of Pressure Vessels Reactors.

Corrugated PTFE Gaskets - CPG Advantages. Gasket design for pressure vessel. MhT is measured at the point 13 up the triangle the centroid of the force.

I am not aware of any real method for calculating the ligament we typically use the E dimensions in TEMA Table D5 as the gasket half-width. You can also reach us. Gasket design for pressure vessel Ditulis Todd Franklin Minggu 27 Maret 2022 Tulis Komentar Edit.

For colder-service conditions A-106 and API 5L Grade B can operate to 50F if the maximum operating pressure is less than 25 of the maximum allowable design pressure and if. ASME Boiler and Pressure Vessel Code Calculations. The very important phase to construct a pressure vessel is DESIGN PHASE Design phase is carried out with the care with the help of CODES.

Of the gasket there is no pressure at the gasket OD and thus no leakage. UKL have various types of metallic gasket ranges which can withstand high pressure in the high pressure vessel application. The flange class or pressure rating system extends to gaskets designed for those flanges.

The pressure if it were to be released would be dangerously high perhaps even explosively destructive. The values of which ensure the safety performance of vessel. For openers this is an engineering scenario that implies a substantial stress factor.

A gasket is designed in such way that the flanges should be able to create the specific amount of compressive load on the surface of the vessel. At operating condition Wm1 Wm2 πbGy Wm1 H Hp P 2bπGmP Where G diameter at the location of gasket load reaction G Mean diameter of gasket for b0 025 inch H Total hydrostatic end force P Hp Force required to keep the gasket without leaking or in seating condition 2bπGmP Bolt design conti Minimum bolting. It created an seal with no pressure.

Pressure vessels that meet any of the following standards shall be deemed as meeting the requirements of 6621423. Test information is available for. Soft gaskets such as cork rubber vegetable fiber graphite or asbestos are usually plain with a relatively smooth surface.

HT is the average pressure along the length. Flange and gasket calculations. How does the term High-Pressure Vessel impact gasket design.

The overall pressure rating of the gasket ultimately depends on the material used for the gasket and the operating temperature. The decision as to which standard is to. To properly design a pressure vessel it is necessary to understand Section VIII of course and additionally the designer will need to be familiar with Sections II V and IX.

This table gives a list of many commonly used gasket materials and contact facings with suggested design values of m and y that have generally proved satisfactory in actual service when using effective gasket seating width b given in the table following. If that pressurized fluid is to be reliably contained at each and every vessel seam capable gasket. Boiler and Pressure Vessel is divided into the following sections.

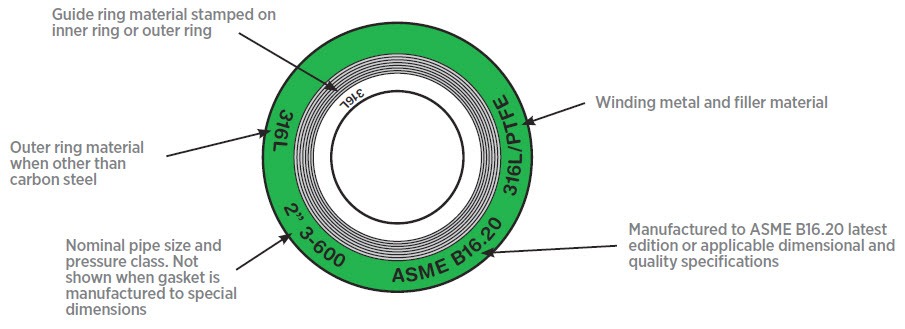

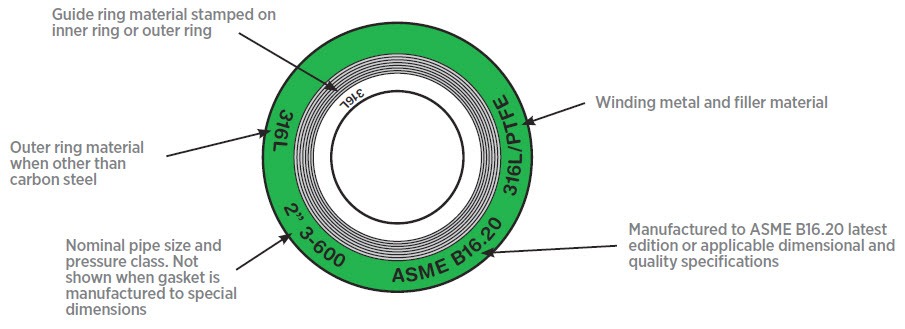

Types Of Gaskets For Flanges Soft Spiral Ring Joint Projectmaterials

Ring Joint Gaskets Fajar Benua Indopack

Types Of Gaskets For Flanges Soft Spiral Ring Joint Projectmaterials

How To Choose The Right Gasket Www Pipelinedubai Com

What Are M And Y Gasket Design Constants And How Are They Used Pumps Systems

Asme Boiler And Pressure Vessel Code Calculations Coding Vessel Boiler

0 comments

Post a Comment